REPORT OF THE DECEMBER 18, 2008 ADVANCED ENGINE TECHNOLOGIES, INC. ANNUAL SHAREHOLDER MEETING

Carroll Shelby Enterprises, Inc., 19021 S. Figueroa St., Gardena, California 90248 (310) 538-2914

Advanced Engineering Technologies, Inc. held its annual shareholder meeting at 11:00 am on Thursday, December 18, 2008 at Carroll Shelby Enterprises which houses OX2 engine development facilities. Attending the meeting were John Luft, Chief Operating Officer; Neil Cummings, Secretary and Legal Counsel; a Gilderman & Associates accounting firm representative; a Robert E. Petersen Trust Fund management representative from Whittier Trust Company; Mike Edwards, Chief Engineer; David Lee, an engineering consultant from Weant Engineering; plus 4 AET shareholders. No members of AET's Board of Directors were present.

Carroll Shelby Enterprises, Inc., 19021 S. Figueroa St., Gardena, California 90248 (310) 538-2914

Advanced Engineering Technologies, Inc. held its annual shareholder meeting at 11:00 am on Thursday, December 18, 2008 at Carroll Shelby Enterprises which houses OX2 engine development facilities. Attending the meeting were John Luft, Chief Operating Officer; Neil Cummings, Secretary and Legal Counsel; a Gilderman & Associates accounting firm representative; a Robert E. Petersen Trust Fund management representative from Whittier Trust Company; Mike Edwards, Chief Engineer; David Lee, an engineering consultant from Weant Engineering; plus 4 AET shareholders. No members of AET's Board of Directors were present.

The meeting began with a vote for the AET Board of Directors. Out of 33,885,000 AENG shares outstanding, 13,652,804 shares were voted including 13,000,000 shares representing the Petersen Trust. This was only 40% of outstanding shares and failed to meet the 51% quorum required by AET bylaws to hold a valid BoD election. Carroll Shelby, Alexandria Phillips, and Noel Holmes continue as the AET Board of Directors. The issue was raised that many AENG shareholders whose shares are held in "street name" are not receiving proxy statements. John Luft claimed AET is properly mailing out proxy statements to all listed sharholders and it is the responsibility of the financial institutions holding shares in "street name" to forward proxy materials to their clients. It was asked how many shares are held in "street name", and John Luft replied it was about 9,000,000 shares. Clearly those 9,000,000 were not represented. After some discussion, it was decided that any shareholder holding AENG shares in "street name" may call AET, (310) 538-2914, to have proxy statements directly mailed to their address provided they also fax or mail copies of statements from their brokers to AET which offer some proof of AENG share ownership. If, in the future, it becomes necessary to actually replace BoD members, those 9,000,000 shares need to be reached to be able to hold a certifiable election. This still leaves the question of why proxy statements are failing to reach shareholders unresolved, and shareholders who did not receive their AET proxy statements need to call AET to drive home this point.

Following, the vote, John Luft gave a brief overview of AET's operations and goals. The immediate goal is to get to and demonstrate a stable and reliable Design Level #3 OX2 engine and a marketable 30 kw genset as quickly as possible. Operating costs have been held under control by reducing permanent engineering staff to just one engineer, Mike Edwards. Supporting staff also includes a fulltime CNC machinist and a couple of mechanics including technician Steve Wells who runs the dyno testing. Engineering consultants are contracted as needed for CAD, electrical, and engine control systems. Monthly operational costs are about $80,000 a month. AET continues to retain Gilderman & Associates for accounting, the same firm employed by AET for SEC reporting prior to delisting AENG stock. Some failures during engine and generator testing have resulted in delays and the need for additional engineering expense. Because of a failure of one of the control electronics units provided by Dynotek for the Dynotek generators, a new, more reliable control electronics unit needs to be sourced and purchased which will require more than $200,000 in necessary added expense. It is also necessary to develop a suitable electronic throttle control to maintain optimal OX2 engine speed. Other engineering issues and durability testing need to be resolved and completed. AET reserves are currently just under $500,000. Hence, AET will need to raise additional funds through the sale of AENG stock. Up to less than 17 million shares could be sold limited by a 50 million total share cap. John Luft pledged his fiduciary responsibility to try to increase AENG share price to obtain the most favorable terms for current AET shareholders when raising funds. There are a number of potential investors who are open to funding AET, including Carroll Shelby. A presentation has been made to Whittier Trust, managers of the Petersen Trust Fund, which was well received. Neil Cummmings has been separately involved with the development of a Maglev rail system, to operate between Anaheim and Las Vegas, and brought up the OX2 generator in discussions with General Atomics engineers who became very interested. General Atomics is responsible for the development of propulsion and electrical delivery systems for the Maglev rail system, and the small, lightweight OX2 generator is a very suitable and attractive package for General Atomics applications.

Mike Edwards began his presentation by summarizing some of the advantages of the OX2 generator. For one, it is a variable speed generator, so if the electrical demand is less than 30 kw, the engine speed is automatically reduced consuming less fuel to produce the lower kw power needed. The electronic controller always maintains the correct voltage and frequency independent of engine speed. In hybrid cars, the engine to run the generator is always run at one speed, the speed at which the engine is most efficient, always consuming fuel at the same rate. The latest OX2 Level 3 engine is able to run smoothly down to about 400 rpm, producing 10 kw at about 500 rpm. On the higher power end, while AET is currently developing a 30 kw generator, in free spin tests, the Dynotek generator produces over 50 kw at around 1200 rpm, opening the possibility of developing a 60 kw generator using the same Danotek unit at higher rpm.

The main attraction of the OX2 generator is that it is 1/3 the size, 1/2 the weight, and runs at lower rpm than typical industry standard diesel generators. Cost-wise, diesels currently run about $350/kw and the Capstone Microturbine generator runs around $1000/kw. OX2 is shooting for $500/kw, with its small size making it the desirable choice. Upcoming environmental regulations may significantly raise the cost of diesel generators. In 2007 rules requiring scrubbers to reduce diesel soot and particulates went into effect. California regulations requiring controls for NOx emissions begin to go into effect in 2010, and in years shortly beyond, these rules will be stiffer and retroactive forcing many diesel trucks and equipment out of service. Caterpiller recently signed a deal with Navistar and will no longer build and furnish diesel engines to other on-highway diesel truck builders. NOx controls for diesel are expensive and reduce engine efficiency. EGR systems to reduce NOx add heat and wear. NOx selective catalytic converters require using and storing an extra fluid, meaning extra maintenance to keep diesel powered pumps and generators running in remote fields and locations. The current AET OX2 and GM powered variable speed generators will run on propane.

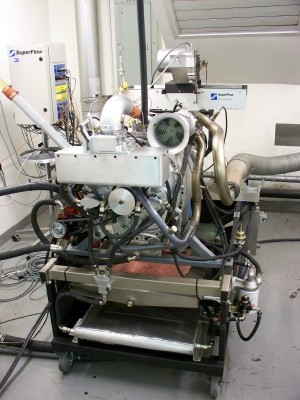

Over the last year, AET has fully installed and is using its new dyno for testing, and AET has built its second and third Level 3 OX2 engines. Engine 1 has been scrapped with its case and turbo going to Engine 2, leaving two engines for development and testing, Engine 2 and Engine 3. Distribution of oil in the engine has been a problem, with air bubbles becoming trapped in the oil, foaming as the oil is thrust and slapped to the sides of the engine by the spinning cylinder block. The foam impedes oil flow and leads to engine overheating. To prevent formation of foam, a 2-stage dry sump oil pump system has now been employed. One stage, the scavange pump, sucks oil from the oil pan through filters into a canister where the oil settles and air bubbles released. The second stage pulls oil from the canister and pumps it back into the engine. This system seems to maintain oil temperature okay, but the engineers have decided to experiment with operating the OX2 in a vertical position, with the heavier generator side facing down, to more evenly distibute oil and to keep oil out of the cylinders for better ignition and firing. In the horizontal position, oil tends to get into cylinders near the bottom slowing firing in those cylinders. A reliable, proven triple seal should prevent oil from dripping into the generator. Engine 2 will be tested in vertical test stand which has already been built. During horizontal testing, a turbo on Engine 2 failed, likely due to low oil pressure. Another separate stage may be added to the oil pump system to provide higher oil pressure to the turbo, or a mechanical supercharger with lower boost might be used. The vertical orientation also means an OX2 genset would have the selling advantage of an even smaller footprint using less floor space.

Previously, Engine 1 achieved 320 ft-lbs at 48 hp. For a 30 kw generator, only 250 ft-lbs at 45 hp is required. Engine 2, using high compression ratio pistons, achieved 265 ft-lbs. Engine 3, using lower compression ratio pistons, has achieved over 300 ft-lbs and also runs quieter and smoother at lower rpm. Danotek generator testing is currently being done using the GM propane engine powered variable speed generator with a mechanical speed governor. During this testing, one of the power electronics units failed due to a voltage spike and arcing. It was determined that Danotek had sourced the power electronics from Youtility and that the unit is basically a benchtest version, lacking the durability required for field use. Youtility no longer makes such units for applications less than 100 kw, so AET engineers have had to source a new power electronics company. First AET looked at Morey Corp who makes proprietary electronic controls for Caterpillar. Then AET determined the proprietary systems use electronics designed by ECE, Electronic Concepts and Engineering, Inc., a company established in power generation control. ECE now appears to be the source AET will be using for its power electronics.

While current variable speed generator testing is being done with a mechanical speed governor, AET plans call for an Electronic Throttle Control (ETC). AET has determined that no suitable off-the-shelf stand-alone throttle control system is available. Automobile makers incorporate their ETC systems into the car's ECU, electronic control unit, and thus it is not available as a separate unit. It is necessary for AET to design and develop its own ETC. To that end, AET has contracted with Weant Engineering, owned by Bob Weant who has a prior relationship with Carroll Shelby International. (This appears to be Bobby Ray Weant of Vehicle Enhancement Systems, Inc., Rock Hill, SC, a heavy hitter with lots of patents to his name.) David Lee, a Weant engineer, discussed the ETC design at the meeting. The ETC will have a variety of inputs and outputs and will be controlled via a feedback loop which includes a generator output power controller and an interface controller (supplied by ECE) to maintain the correct engine speed and electrical power output. The ETC may be built in two versions, one version for commercial gensets and one version for high-performance automotive use, both of which AET could sell as a stand-alone product in addition to the OX2, the OX2 genset, and the GM powered variable speed generator package. (Note AET is also considering a Ford 4 cylinder propane engine in addition to the GM engine.) The computerized control system also provides the potential to remotely monitor and control OX2 powered generators and pumps in the field from an office computer.

The problems AET has encountered over the last year has delayed 100 hour durability testing. Another problem that still must be corrected before the 100 hour testing begins is excessive blow-by gas accumulating at the top of the engine. Plans call for simultaneous endurance testing of Engine 3 on the new dyno and component development and generator integration using Engine 2 on the vertical test stand during the first half of 2009. Simultaneously Weant Engineering is to develop the ETC during the first half of 2009. Power and interfacing electronics development will take place at ECE during the last three quarters of 2009.

A thick handout including charts, photos and outlines summarizing the content of the annual shareholder meeting was passed out to shareholders. The content of this handout will be available on AET's official http://www.ox2engine.com/ website. John Luft also stated a press release summarizing the meeting will be issued in January 2009 followed by additional press releases during the course of the year.

The presentations were followed by running demonstrations of the OX2 Engine 3 on the new dyno and the GM powered variable speed generator. Engine 3 was only run briefly due to an unexpected technical problem. The AET 30 kw variable speed generator was run hooked up to a 1000 watt metal halide flood light and compared to a portable Coleman 6 kw diesel generator powered 4 flood light construction site plant of similar physical size. For the same size, the AET variable speed generator can power more than 20 such flood lights. Also on display was Engine 2 configured with the Danotek generator in the vertical test stand, as well a a display of various Level 3 parts and components.

Despite the problems and delays, AET is still on course to create world class quality products. By utilizing the engineering services of such highly competent and respected firms as ECE and Bob Weant, along with the high competence of AET's own engineer, Mike Edwards, AET's goals for the OX2 are well within reach.

OX2 Engine #2 and Danotek Generator on the Vertical Test Stand - Note Oil Pump at Left

OX2 Engine #2

New Dyno Console

Mike Edwards and Steve Wells at the New Dyno Console

OX2 Engine #3 on the New Dyno - Note Oil Canister at Left

OX2 Engine #3 on the New Dyno

Various Parts from OX2 Engine #1

Various Parts from OX2 Engine #1

AET 30 kw Variable Speed Generator Running and Powering Flood Light

Coleman 6 kw Diesel Generator 4 Flood Light Power Plant